Model 30-90Screw Diameter φ30-90 mmL/D Ratio 26:1/25:1Extrusion Output 25-250 kg/hMain Motor 18-63 KWOutlet Diameter 0.2-35 mmSpeed 10-600 m/minApplication Extrusion line for industrial and workshop crane wire ropes

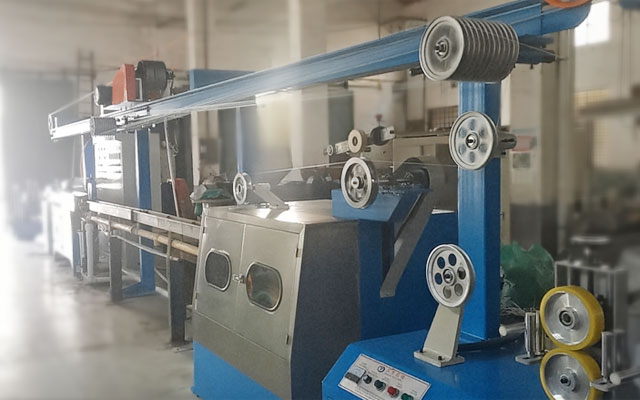

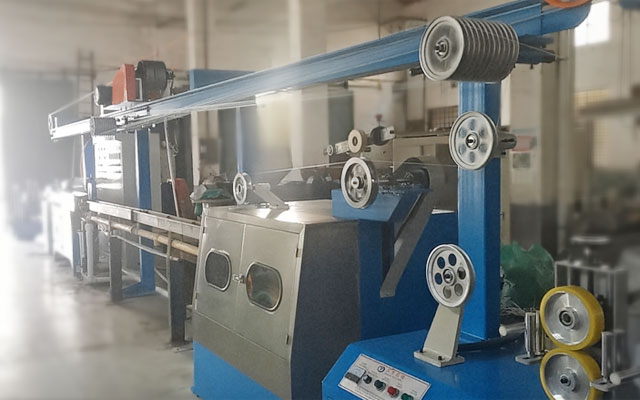

Extrusion Line for Industrial and Workshop Crane Wire Ropes

The extrusion production line for industrial and workshop crane wire ropes is specialized equipment designed for producing plastic-coated wire ropes used in factory and workshop lifting equipment. This line applies a continuous polymer layer (typically PVC, PU or specially formulated coatings) onto standard crane wire ropes through melt extrusion process, creating protected wire ropes suitable for diverse industrial environments.

Core Purpose and Product Value:Core Purpose: To enhance standard crane wire ropes with protective coating that withstands industrial operating conditions while maintaining flexibility and inspection capability.

Product Value:

Contamination Protection: Prevents penetration of dust, metal particles, and other industrial contaminants into the wire rope structure.

Controlled Wear Characteristics: Coating reduces internal friction between wires and protects against external abrasion from drums and sheaves.

Workplace Safety: Color coding allows immediate identification of rope capacity and application; smooth surface prevents snagging and hand injuries.

Corrosion Resistance: Suitable for humid environments, chemical exposures, and outdoor applications where basic protection is required.

Line Composition

This production line is configured for medium-duty operation, balancing precision with operational flexibility for various industrial rope specifications:

1. Modular Pay-off SystemFunction: Handles standard industrial rope reels (typically 1-5 tons) with adjustable tension control.

Key Feature: Versatile mounting system for different reel types; incorporates brake modulation for consistent tension management.

2. Adaptive Pre-treatment SystemFunction: Prepares wire rope surface for optimal coating adhesion.

Key Feature: Combination of mechanical cleaning and controlled heating ensures proper surface condition without material degradation.

3. Medium-capacity ExtruderFunction: Provides precise melt delivery for consistent coating application.

Key Feature: Standard screw diameters (45-90mm) with precision temperature zones; optimized for common coating materials like PVC and PU.

4. Standard Crosshead Die SystemFunction: Applies concentric coating with precise thickness control.

Key Feature: Quick-change die inserts allow rapid size changes; designed for easy maintenance and cleaning.

5. Compact Cooling SystemFunction: Solidifies coating while maintaining material properties.

Key Feature: Multi-zone water baths with temperature gradation control; space-efficient design for factory installation.

6. Precision Traction SystemFunction: Maintains consistent line speed and product dimensional stability.

Key Feature: Dual-track caterpillar puller with adjustable pressure; synchronized with main drive system.

7. Flexible Take-up UnitFunction: Winds finished product according to customer requirements.

Key Feature: Accommodates various reel sizes; programmable traverse for optimal winding patterns.

8. User-friendly Control SystemFunction: Manages all production parameters and operational sequences.

Key Feature: Touchscreen interface with recipe storage; diagnostic functions and production reporting capabilities.

Extrusion Line for Industrial and Workshop Crane Wire Ropes Datasheet

| Model |

30 |

40 |

50 |

60 |

70 |

80 |

90 |

| Screw Diameter (mm) |

φ30 |

φ40 |

φ50 |

φ60 |

φ70 |

φ80 |

φ90 |

| Screw L/D Ratio |

25:1 |

25:1 |

26:1 |

26:1 |

26:1 |

26:1 |

26:1 |

| Extrusion Amount (kg/hr) |

25 |

40 |

70 |

100 |

140 |

200 |

250 |

| Outlet Wire (mm) |

0.2-1 |

0.4-3 |

0.8-5 |

1-8 |

2-15 |

3-25 |

5-35 |

| Total Power (KW) |

18 |

20 |

25 |

33 |

40 |

55 |

63 |

| Traction Power (KW) |

2.2 |

2.2 |

4 |

4 |

4 |

5.5 |

5.5 |

| Production Speed (m/min (Max.)) |

600 |

600 |

600 |

500 |

500 |

300 |

300 |

| Take-up Spool (mm) |

φ200-400 |

φ300-500 |

φ400-630 |

φ400-630 |

φ500-630 |

φ800-1000 |

φ1000-1250 |

Extrusion Line for Industrial and Workshop Crane Wire Ropes Application

The coated wire ropes produced are essential components in various industrial material handling applications:

1. Factory Workshop CranesApplication Areas: Overhead bridge cranes, jib cranes, and monorail systems.

Advantages:

Extended Service Intervals: Reduced internal wear extends rope life in frequent-cycling applications.

Clean Operation: Coating contains wire rope lubricant and prevents contaminant release in clean manufacturing areas.

Visual Inspection: Color contrast makes broken wires and damage easily detectable during routine checks.

2. Manufacturing Process CranesApplication Areas: Production line hoists, assembly area cranes, and maintenance cranes.

Advantages:

Environmental Resistance: Withstands typical industrial atmospheres including moderate humidity and temperature variations.

Workplace Organization: Color coding helps identify different crane systems and their safe working loads.

Reduced Maintenance: Coating preserves internal lubrication and reduces scheduled maintenance requirements.

3. Specialized Industrial ApplicationsApplication Areas: Steel processing, metal fabrication, warehousing, and assembly operations.

Advantages:

Process Compatibility: Suitable for environments with moderate exposure to oils, coolants, and industrial chemicals.

Operational Safety: Enhanced visibility and handling characteristics contribute to safer working conditions.

Cost Efficiency: Balanced performance characteristics provide optimal lifetime value for general industrial use.