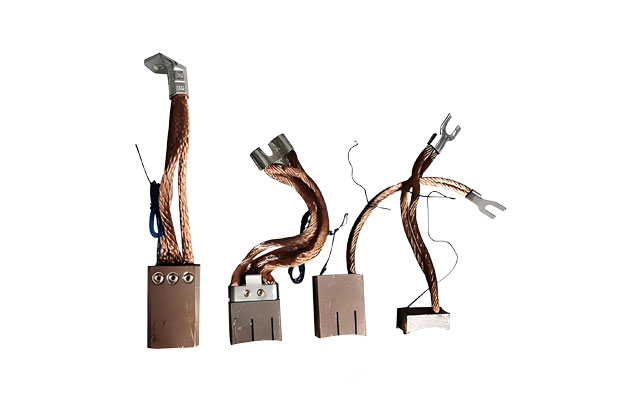

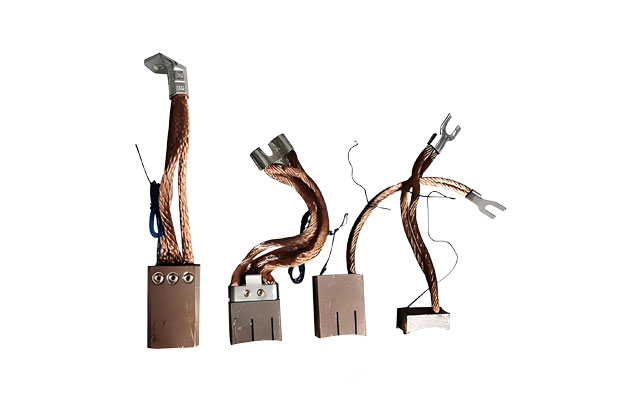

Carbon Brush

Carbon brushes for wire drawing machines are key components used to conduct current and reduce friction. They are usually installed on the conductive wheels or motor rotors of wire drawing machines to ensure stable current transmission during the drawing process of metal wires (such as copper, aluminum, steel, etc.) while reducing mechanical wear.

Core Functions

Current Transmission: Provides stable current in electroplating or electrolytic wire drawing processes.

Friction Reduction: Protect conductive wheels or slip rings and reduce metal contact losses.

Signal Transfer (partial application): used in precision measurement or control systems.

Carbon Brush Datasheet

/

Carbon Brush Application

Carbon brush for wire drawing machine is a key component used to conduct current and reduce friction. It is usually installed on the conductive wheel or motor rotor of the wire drawing machine to ensure stable current transmission of metal wires (such as copper, aluminum, steel, etc.) during the drawing process, while reducing mechanical wear. It is mainly used in the following situations:

Traditional wire drawing machine: Conducts current to the wire, used for electroplating or annealing processes.

High speed continuous drawing: Reduces arcing and wear between the conductive wheel and the wire.

Electrolytic polishing wire drawing: Works stably in acidic/alkaline environments.

Special wire processing: Such as superconducting wire, medical guide wire and other precision fields.