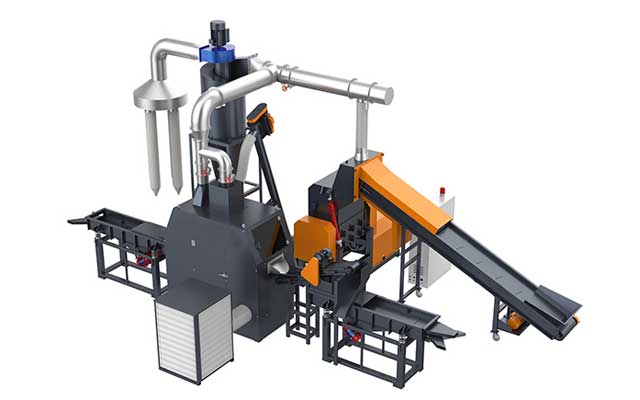

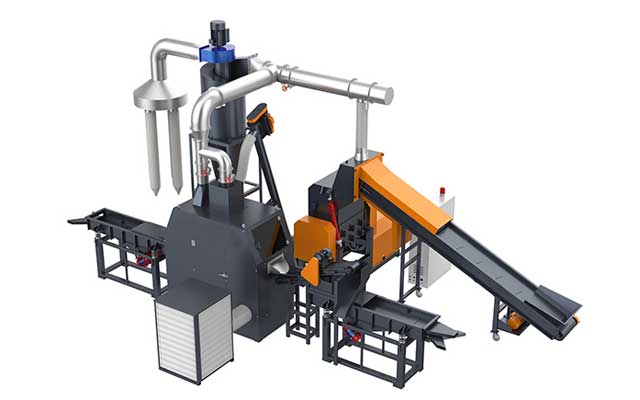

Model 60-2000Power 5-320 KWProcessing Capacity 30-2000 kg/h Size /

Cable Granulator

A cable granulator is an environmentally friendly equipment designed for recycling waste wires and cables. It mechanically separates copper from plastic insulation to produce high-purity "copper rice" (granulated copper) and reusable plastic pellets.

Working Principle

The machine separates copper and plastic through a series of processes including crushing, sorting, and vibrating screening.

Core Process: Crushing → Air separation/Electrostatic separation → Vibrating screening → Dust collection and removal.

Key Features

Eco-friendly & High Efficiency: Utilizes physical separation without burning or chemical pollution, achieving a copper recovery rate of over 99%.

High Automation: Equipped with a PLC control system, minimizing manual intervention.

Economic Value: The separated copper rice can be directly used for smelting or further processing, while plastic pellets can be recycled.

Classification of Cable Granulators

1. By Processing CapacitySmall-scale Cable Granulator: Processing capacity of 100-500 kg/h, suitable for individual operators or small recycling stations.

Medium-scale Cable Granulator: Processing capacity of 500-1000 kg/h, ideal for medium-sized recycling enterprises.

Large-scale Cable Granulator: Processing capacity of 1-3 tons/h, designed for industrial-scale recycling operations.

2. By Separation TechnologyDry-type Cable GranulatorEmploys air separation or vibrating screening, requiring no water and producing no wastewater, making it suitable for dry environments.

Advantages: Energy-efficient, environmentally friendly, and easy to maintain.

Wet-type Cable GranulatorUses water flow to wash and separate copper from plastic, achieving more thorough separation but requiring wastewater treatment.

Advantages: Higher purity separation, suitable for complex cables.

Electrostatic Separation Cable GranulatorLeverages the conductivity difference between copper and plastic for high-voltage electrostatic separation.

Advantages: High precision, though at a higher cost.

3. By Automation LevelSemi-automatic: Requires manual assistance for feeding or sorting; more affordable.

Fully Automatic: Fully automated operation, including conveyor belts and intelligent sorting systems for higher efficiency.

4. By Cable Type CompatibilityMixed-wire Granulator: Capable of processing various mixed cables (e.g., copper, aluminum, thin wires).

Specialized Cable Granulator: Optimized for specific cable types (e.g., automotive wires, communication cables) to enhance separation efficiency.

Cable Granulator Datasheet

| Model |

60 |

200 |

400 |

600 |

| Power |

5 KW |

27 KW |

58 KW |

69 KW |

| Processing Capacity |

30-60 kg/h |

100-200 kg/h |

200-400 kg/h |

300-600 kg/h |

| Size (L x W x H, m) |

/ |

4.7x2.5x2.9 |

12x6.5x4.8 |

12x6.5x4.8 |

| Model |

600L |

800 |

1000 |

1000S |

| Power |

100 KW |

110 KW |

163 KW |

140 KW |

| Processing Capacity |

300-600 kg/h |

400-800 kg/h |

500-1000 kg/h |

500-1000 kg/h |

| Size (L x W x H, m) |

14x6x5 |

14x6x5 |

15x7x5 |

16x7.5x5 |

| Model |

1600 |

2000 |

|

|

| Power |

210 KW |

320 KW |

|

|

| Processing Capacity |

800-1600 kg/h |

1300-2000 kg/h |

|

|

| Size (L x W x H, m) |

/ |

21x13x5 |

|

|

Cable Granulator Application

A cable granulator is an environmentally friendly equipment designed for recycling waste wires and cables. It mechanically separates copper from plastic insulation to produce high-purity "copper rice" (granulated copper) and reusable plastic pellets. It is used for processing various types of waste wires, cables, communication lines, automotive circuits, etc.