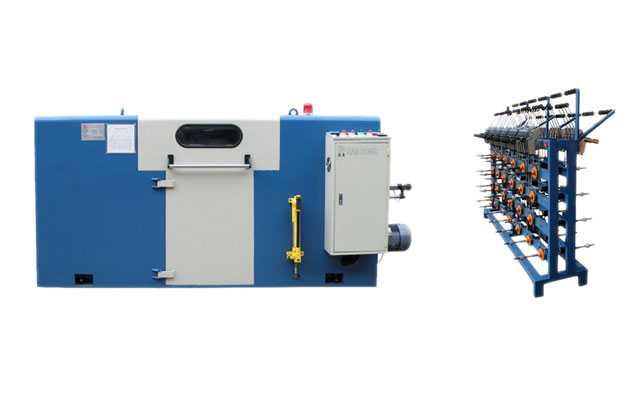

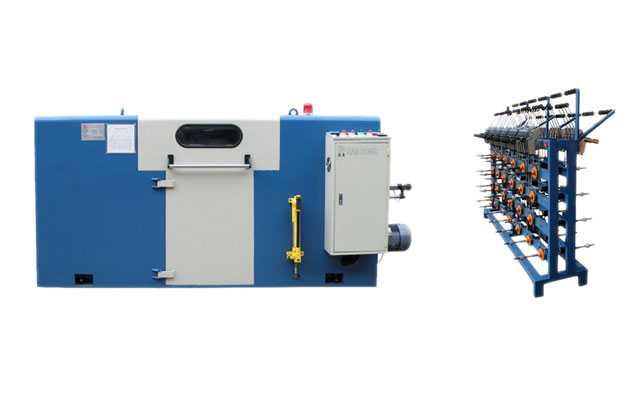

Copper Wire Double Twist Stranding Machine

Our Core Strengths100+ Certified Factories Across All CategoriesMultiple Competitive Quotes Tailored to Your NeedsOne-Stop Export Solutions

| Model | 130 | 200 | 300 | 400 | 500 | 650 | 800 | 1000 | 1250 |

| Inlet Wire Dia. | 0.02-0.03 mm | 0.025-0.08 mm | 0.05-0.28 mm | 0.08-0.45 mm | 0.08-0.45 mm | 0.16-1.00 mm | 0.38-1.00 mm | 0.42-4.00 mm | 1.00-6.00 mm |

| Stranded Cross Section | 0.002-0.03 mm2 | 0.0034-0.035 mm2 | 0.137-0.45 mm2 | 0.35-1.25 mm2 | 0.035-2.00 mm2 | 0.40-6.00 mm2 | 0.80-12.00 mm2 | 1-90 mm2 | 7-200 mm2 |

| Lay Length | 0.75-1.25 mm | 0.94-4.08 mm | 1.34-12.5 mm | 4.06-31.5 mm | 4.22-41.62 mm | 11.15-60.24 mm | 22.51-153.32 mm | 48.10-155.90 mm | 48.10-155.90 mm |

| Rotation Speed | 4000 rpm | 5000 rpm | 3000 rpm | 2500/3500 rpm | 2200/3000 rpm | 1600 rpm | 800 rpm | 500 rpm | 500 rpm |

| Main Motor | 2HP | 3HP | 3HP | 5HP/7.5HP | 5HP/7.5HP | 10HP | 15HP | 20HP | 25HP |

| Lay Direction | S/Z | S/Z | S/Z | S/Z | S/Z | S/Z | S/Z | S/Z | S/Z |

| Traversing Device | / | / | / | / | / | / | / | / | / |

| Braking System | Electronic brake | Electronic brake | Electronic brake | Electronic brake | Electronic brake | Electronic brake | Electronic brake | Electronic brake | Electronic brake |

| Take-up Tension | Magnetic powder clutch control | Magnetic powder clutch control | Magnetic powder clutch control | Magnetic powder clutch control | Magnetic powder clutch control | Magnetic powder clutch control | Magnetic powder clutch control | Magnetic powder clutch control | Magnetic powder clutch control |

| Take-up Spool | φ130 mm | φ200 mm | φ300 mm | φ400 mm | φ500 mm | φ630 mm | φ800 mm | φ1000 mm | φ1250 mm |

| Lifting System | Manual operation | Manual operation | Manual operation | Manual operation | Manual operation | Manual operation | Manual operation | Manual operation | Manual operation |

| Noise Level | 75 dB | 75 dB | 75 dB | 75 dB | 75 dB | 80 dB | 80 dB | 80 dB | 85 dB |

Sales

86 185 7036 4737

sales@fulcha.com

Wechat: fulcha