Model C/M/F/U/E SeriesNo. of Wires 1Inlet Wire Diameter 0.8-8 mmOutlet Wire Diameter 0.1-4.5 mmLine Speed (Max.) 1000-1500 m/minNo. of Dies (Max.) 17-22Motor Power 18.5-45 kWTake-up Power 3.7-15 KWConductor Type Brass wireDrive System Frequency converter

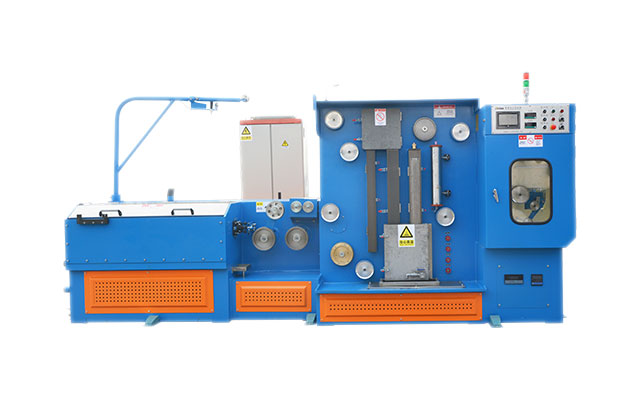

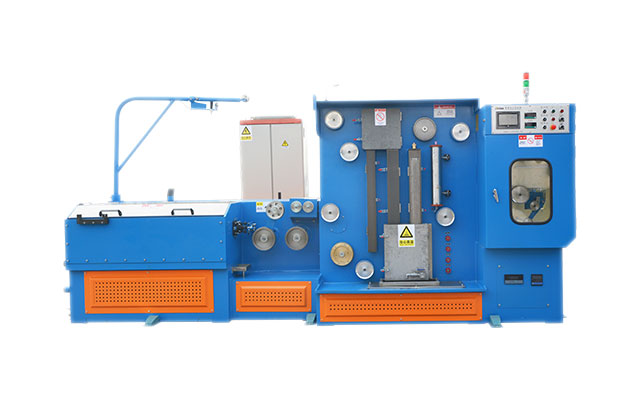

Brass Wire Drawing Machine

The brass wire drawing machine is a specialized equipment used to process brass rods (usually ranging from 8 mm to 20 mm) into brass wires of different diameters (such as 0.1 mm to 6 mm) through multiple passes of stretching. Brass (copper zinc alloy) has excellent conductivity, ductility, and corrosion resistance, and is widely used in industries such as electronics, hardware, decoration, and cables.

Main Structure

Pay-off system: Active/passive pay-off, equipped with tension control.

Wire drawing host: Mold box, wire drawing wheel (tower wheel or inline type), lubrication and cooling system.

Annealing device: Eliminates work hardening and improves wire flexibility.

Take-up system: I-shaped wheel or double disc winding, precise wire arrangement ensures neat winding.

Control system: PLC+human-machine interface (HMI), realizing the adjustment of parameters such as speed, tension, temperature, etc.

Brass Wire Drawing Machine Datasheet

| Item/Model |

M Series |

F Series |

| No. of Wires |

1 |

1 |

| Inlet Wire Dia. |

1.8-3.0 mm |

0.8-1.2 mm |

| Outlet Wire Dia. |

0.4-1.6 mm |

0.1-0.32 mm |

| Line Speed (Max.) |

1000 m/min |

1500 m/min |

| No. of Dies (Max.) |

17 |

22 |

| Slip Ratio of M/C |

15% |

/ |

| Slip Ratio of Fixed Speed Wheel |

10% |

/ |

| Main Motor |

45 KW |

18.5 kW |

| Take-up Motor |

15 KW |

3.7 KW |

| Annealing Motor |

120 KVA |

12 KVA |

| Annealing Method |

DC three-section annealing |

DC four-section annealing |

| Traverse Method |

Gear motor |

/ |

| Brake |

Pneumatic brake |

Pneumatic brake |

| Take-up Spool |

φ630 mm |

φ250 mm |

Brass Wire Drawing Machine Application

The brass wire drawing machine is the core equipment for brass wire processing, with diverse classifications and wide applications. Specifically, as follows:

Electronic EnterprisesElectronic connectors (such as mobile phone/computer interface terminals).

Enamel wire (electromagnetic wire, used for motor and transformer windings).

Shielded wire (shielding layer of coaxial cable and communication cable).

Hardware and DecorationZipper teeth (brass zippers for clothing and luggage).

Decorative lines (metal edging of furniture and crafts).

Rivets and screws (precision hardware components).

Industrial and Special PurposeWelding wire (brass gas welding wire, brazing material).

Spring wire (elastic element, precision spring).

Medical wires (such as dental alloy wires).