Model F SeriesNo. of Wires 1Inlet Wire Diameter 0.8-1.2 mmOutlet Wire Diameter 0.1-0.32 mmLine Speed (Max.) 1500 m/minNo. of Dies (Max.) 22Motor Power 18.5 kWTake-up Power 3.7 KWConductor Type Brass wireDrive System Frequency converter

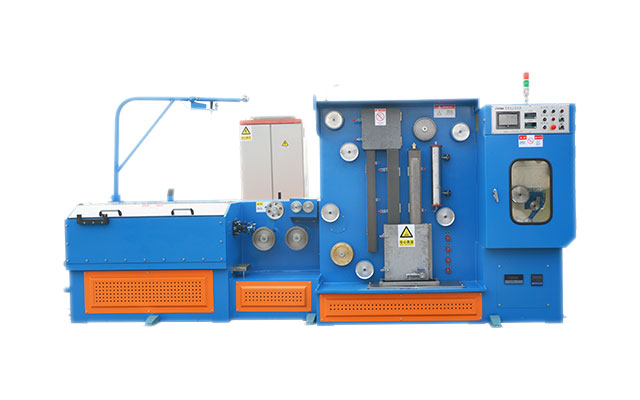

Fine Brass Wire Drawing Machine

The fine brass drawing machine is a key equipment specifically designed to process medium brass wire with a diameter of 0.8 mm to 1.2 mm into fine brass wire with a diameter of 0.1 mm to 0.32 mm through multiple passes of stretching.

Main Structure

Pay-off system: Active/passive pay-off, equipped with tension control.

Wire drawing host: Mold box, wire drawing wheel (tower wheel or inline type), lubrication and cooling system.

Annealing device: Eliminates work hardening and improves wire flexibility.

Take-up system: I-shaped wheel or double disc winding, precise wire arrangement ensures neat winding.

Control system: PLC+human-machine interface (HMI), realizing the adjustment of parameters such as speed, tension, temperature, etc.

Fine Brass Wire Drawing Machine Datasheet

| Item/Model |

F Series |

| No. of Wires |

1 |

| Inlet Wire Dia. |

0.8-1.2 mm |

| Outlet Wire Dia. |

0.1-0.32 mm |

| Line Speed (Max.) |

1500 m/min |

| No. of Dies (Max.) |

22 |

| Slip Ratio of M/C |

/ |

| Slip Ratio of Fixed Speed Wheel |

/ |

| Main Motor |

18.5 kW |

| Take-up Motor |

3.7 KW |

| Annealing Motor |

12 KVA |

| Annealing Method |

DC four-section annealing |

| Traverse Method |

/ |

| Brake |

Pneumatic brake |

| Take-up Spool |

φ250 mm |

Fine Brass Wire Drawing Machine Application

The fine brass wire drawing machine, as a precision metal processing equipment, plays an irreplaceable role in modern industry. Its main application areas and technical characteristics are as follows:

Manufacturing of Electronic ComponentsMicro connectors: used for precision connectors such as Type-C interfaces for mobile phones/computers, SIM card slots, semiconductor leads, bonding wires for chip packaging, relay contacts, and key conductive components for electromagnetic relays.

Precision Instrument FieldMedical equipment: orthodontic archwire, endoscope guide wire.

Optical instruments: barrel focusing thread, precision gear shaft, special surface coating treatment.

High End Consumer GoodsJewelry craftsmanship: 18K gold alloy jewelry skeleton, precision woven jewelry thread, surface polishing requires mirror effect.

Instrument manufacturing: piano stringer components, brass instrument pistons.

Industrial Special ApplicationsMicro spring: a buffer component for electronic devices.

3D printing materials: substrates for sintering metal powders.