Model 50-90Screw Diameter φ50-90 mmL/D Ratio 26:1Extrusion Output 70-300 kg/hrMain Motor 11-75 KWOutlet Diameter 0.75-50 mmSpeed 300-500 m/minApplication BV, BVR, BVV, RV, etc. insulated wire

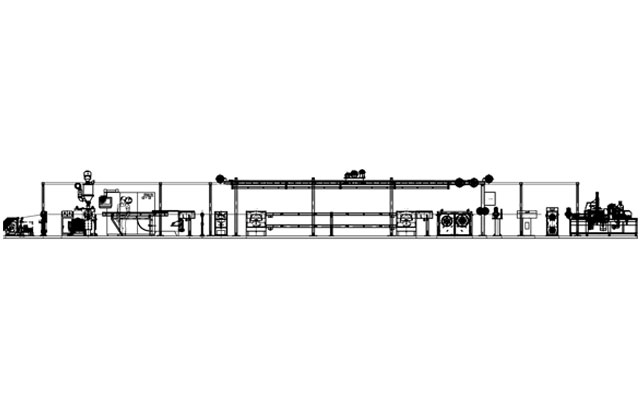

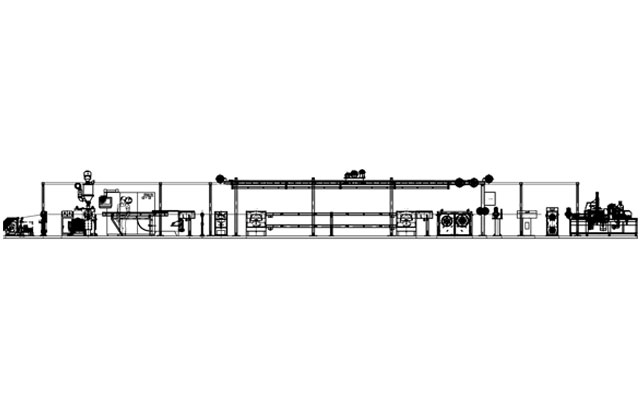

BVV Sheathed Wire Extrusion Line

BVV wire is a copper core PVC insulated PVC sheathed cable. B (Building Wire): Refers to wires that are suitable for building wiring. V (PVC insulation): Indicates that the wire uses polyvinyl chloride (PVC) material as the insulation layer. V (PVC sheath): indicates that there is also a layer of PVC sheath on the outside of the wire to provide additional protection.

Structure of BVV WiresBVV wires usually consist of three parts: copper conductor, PVC insulation layer, and PVC sheath:

Copper conductor: Responsible for conducting current, usually using high-purity oxygen free copper to improve conductivity and durability.

PVC insulation layer: Provides basic electrical insulation, prevents current leakage, and improves safety.

PVC sheath: Increases mechanical strength and prevents damage to wires from external environments such as moisture, friction, etc.

The BVV sheathed wire extrusion line is a complete set of equipment specifically designed for producing copper core polyvinyl chloride insulated polyvinyl chloride sheathed circular cables (BVV). Through secondary extrusion technology, the insulation layer and sheath layer are continuously wrapped to manufacture double protection cables that meet standards.

Composition of Production Line

TConductor Processing SystemCopper conductor straightening device (± 0.1mm accuracy);

Active pay off rack: Equipped with tension feedback control.

Double Layer Extrusion SystemMain extruder: PVC insulation layer extrusion;

Auxiliary extruder: PVC sheath layer extrusion;

Co extrusion die head: Pressure balance design.

Cooling SystemInsulation cooling tank (3-stage gradient cooling);

Sheath cooling groove (5-stage spray cooling);

Intelligent control of water temperature (± 1 ℃).

Linkage Control DevicePLC synchronous control system;

Double traction wheel speed matching (error ≤ 0.05%).

Detection SystemDual channel spark tester (independent insulation/sheath testing);

Laser caliper (real-time monitoring of double-layer thickness).

Process Flow

Pay-off → Copper conductor pretreatment → Insulation layer extrusion → Primary cooling → Sheath layer extrusion → Secondary cooling → Spark detection → Printing → Automatic take-up.

BVV Sheathed Wire Extrusion Line Datasheet

| Model |

50 |

60 |

70 |

80 |

90 |

| Pay-off Type |

Active or passive |

Active or passive |

Active or passive |

Active or passive |

Active or passive |

| Screw Diameter |

φ50 mm |

φ60 mm |

φ70 mm |

φ80 mm |

φ90 mm |

| Screw L/D Ratio |

25:1 |

26:1 |

26:1 |

26:1 |

26:1 |

| Extrusion Amount |

70 kg/hr |

110 kg/hr |

160 kg/hr |

220 kg/hr |

300 kg/hr |

| Outlet Wire |

φ0.75-4 mm |

φ0.8-8 mm |

φ1.5-12 mm |

φ2-18 mm |

φ6-50 mm |

| Main Motor |

11 KW |

18.5 KW |

37 KW |

55 KW |

75 KW |

| Cooling Device |

U type |

U type |

U type |

U type |

U type |

| Storage Rack |

Horizontal |

Horizontal |

Horizontal |

Horizontal |

Horizontal |

| Traction Power |

4 KW |

4 KW |

4 KW |

5.5 KW |

11 KW |

| Production Speed |

500 m/min (Max.) |

450 m/min (Max.) |

400 m/min (Max.) |

350 m/min (Max.) |

300 m/min (Max.) |

| Take-up Spool |

φ400-630 mm |

φ400-630 mm |

φ500-630 mm |

φ800-1000 mm |

φ1000-1250 mm |

| Coiling Method |

Automatic |

Automatic |

Automatic |

Automatic |

Automatic |

BVV Sheathed Wire Extrusion Line Application

The BVV sheathed wire extrusion line is a complete set of equipment specifically designed for producing copper core polyvinyl chloride insulated polyvinyl chloride sheathed circular cables (BVV). Through secondary extrusion technology, the insulation layer and sheath layer are continuously wrapped to manufacture double protection cables that meet standards.