Model 50-60Screw Diameter φ50-60 mmL/D Ratio 26:1Extrusion Output 70-110 kg/hrMain Motor 11-18.5 KWOutlet Diameter 0.75-8 mmSpeed 450-500 m/minApplication BV, BVV, RV, RVV, etc.

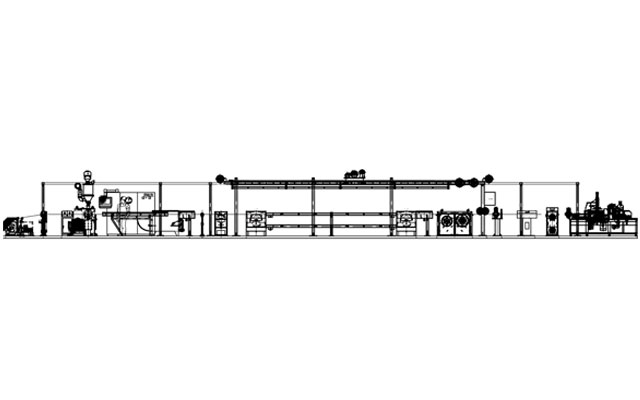

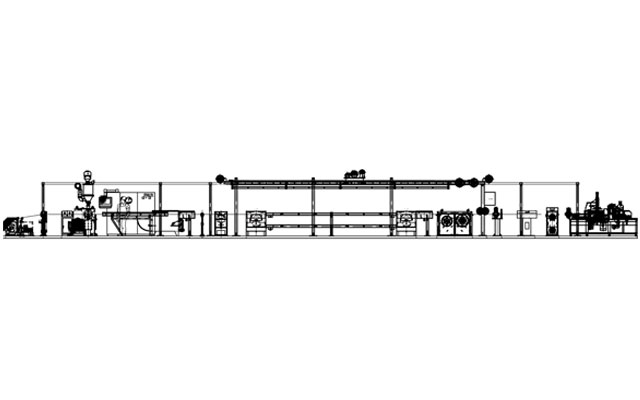

RVV Sheathed Cable Extrusion Line

The full name of RVV cable is copper core PVC insulated PVC sheathed flexible cable, also known as lightweight PVC sheathed flexible wire, commonly known as soft sheathed wire, which is a type of sheathed wire. RVV wires and cables are two or more RV wires with an additional layer of sheath. RVV cable is the most commonly used cable in weak current systems, with an indefinite number of core wires, two or more, and a PVC sheath on the outside. There are no special requirements for the arrangement of core wires. The function of the sheath is to protect the inner protective layer of the cable from mechanical damage and chemical corrosion, and to enhance the mechanical strength of the cable. RVV cables are mainly used as power lines, control lines, and signal transmission lines for electrical appliances, instruments, electronic equipment, and automation devices. They can be specifically used in anti-theft alarm systems, building intercom systems, and other applications.

The RVV sheathed cable extrusion line is a complete set of equipment specifically designed for producing copper core PVC insulated PVC sheathed flexible cables (RVV). Through multiple extrusion processes, the insulation and sheath wrapping of multi-core wire groups are achieved, and lightweight multi-core sheathed cables that meet standards are manufactured.

Composition of Production Line

TConductor Processing SystemCopper conductor straightening device (± 0.1mm accuracy);

Active pay off rack: Equipped with tension feedback control.

Double Layer Extrusion SystemMain extruder: PVC insulation layer extrusion;

Auxiliary extruder: PVC sheath layer extrusion;

Co extrusion die head: Pressure balance design.

Cooling SystemInsulation cooling tank (3-stage gradient cooling);

Sheath cooling groove (5-stage spray cooling);

Intelligent control of water temperature (± 1 ℃).

Linkage Control DevicePLC synchronous control system;

Double traction wheel speed matching (error ≤ 0.05%).

Detection SystemDual channel spark tester (independent insulation/sheath testing);

Laser caliper (real-time monitoring of double-layer thickness).

Process Flow

Multi core conductor pay-off → Synchronous insulation extrusion → Pre cooling and shaping → Stranding into cables → Sheath extrusion → Final cooling → Comprehensive testing → Printing → Automatic take-up.

RVV Sheathed Cable Extrusion Line Datasheet

| Model |

50 |

60 |

| Pay-off Type |

Active or passive |

Active or passive |

| Screw Diameter |

φ50 mm |

φ60 mm |

| Screw L/D Ratio |

25:1 |

26:1 |

| Extrusion Amount |

70 kg/hr |

110 kg/hr |

| Outlet Wire |

φ0.75-4 mm |

φ0.8-8 mm |

| Main Motor |

11 KW |

18.5 KW |

| Cooling Device |

U type |

U type |

| Storage Rack |

Horizontal |

Horizontal |

| Traction Power |

4 KW |

4 KW |

| Production Speed |

500 m/min (Max.) |

450 m/min (Max.) |

| Take-up Spool |

φ400-630 mm |

φ400-630 mm |

| Coiling Method |

Automatic |

Automatic |

RVV Sheathed Cable Extrusion Line Application

The RVV sheathed cable extrusion line is a complete set of equipment specifically designed for producing copper core PVC insulated PVC sheathed flexible cables (RVV). Through multiple extrusion processes, the insulation and sheath wrapping of multi-core wire groups are achieved, and lightweight multi-core sheathed cables that meet standards are manufactured.