Model 50-90Screw Diameter φ50-90 mmL/D Ratio 26:1Extrusion Output 70-300 kg/hrMain Motor 11-75 KWOutlet Diameter 0.75-50 mmSpeed 300-500 m/minApplication BV, BVR, NH-BV, RV, etc.

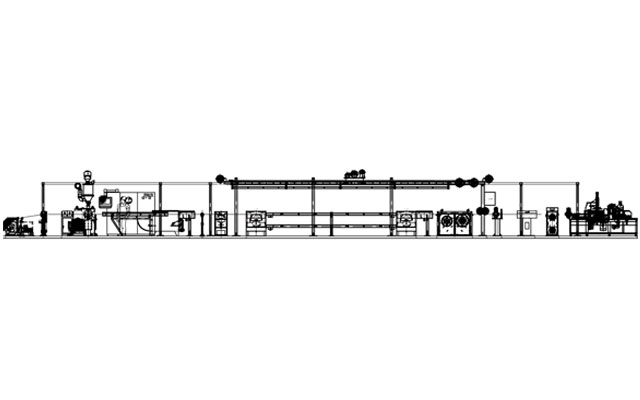

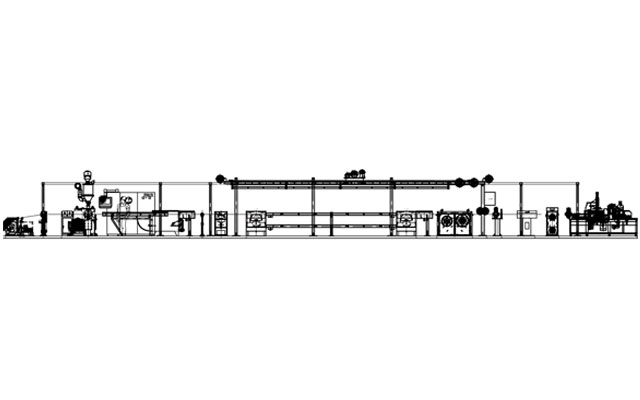

NH-BV Fire-resistant Wire Extrusion Line

NH-BV wire, also known as fire-resistant copper core polyvinyl chloride insulated flexible cable, is made by adding a layer of refractory material on the basis of BV wire (single stranded hard wire).

CharacteristicFire resistance: NH-BV wires undergo special fire-resistant treatment, which can maintain a certain period of time at high temperatures without being damaged, ensuring that the wires will not be immediately cut off in the event of a fire, providing valuable time for people to evacuate.

Insulation: Polyvinyl chloride is used as the insulation material, which has good insulation performance and can effectively prevent current leakage and short circuit.

Wear resistance: The outer protective layer of the wire has a certain degree of wear resistance, which can resist mechanical wear and external environmental erosion.

Other properties include tensile strength, bending performance, moisture resistance, etc., ensuring that the wire can work stably in various environments.

NH-BV wires are commonly used in places with high requirements for fire resistance, such as high-rise buildings, subways, industrial and mining enterprises, communication networks, and electrical installations in unique environments such as metallurgical industry, insulation, crude oil, chemical plants, gas, gasoline, etc. It is also suitable for power lines in AC voltage systems of 450/750V and below, especially emergency circuits.

The NH-BV fire-resistant wire extrusion line is a complete set of equipment designed for manufacturing fire-resistant polyvinyl chloride insulated wires that comply with the GB/T 19216 standard. By adding special fire-resistant materials (such as mica tape) to the insulation layer, the wires can maintain a smooth circuit for 90 minutes in flames above 750 ℃.

Composition of Production Line

The NH-BV fire-resistant wire extrusion line mainly includes the following core equipment:

Pay off Stand: Release copper/aluminum conductors to maintain stable tension.

Preheating Unit: Heat the conductor to improve insulation adhesion.

Extruder: Melt PVC/XLPE and evenly coat the conductor.

Cooling Tank: Segmented cooling and shaping insulation layer.

Haul off: Control the speed of the production line.

Take-up Reel: Automatic winding of finished wires.

Testing Equipment: Spark tester, laser diameter measuring system, etc.

Process Flow

Pay-off → Preheating → Extrusion coating → Cooling and shaping → Spark detection → Printing → Take-up.

NH-BV Fire-resistant Wire Extrusion Line Datasheet

| Model |

50 |

60 |

70 |

80 |

90 |

| Pay-off Type |

Active or passive |

Active or passive |

Active or passive |

Active or passive |

Active or passive |

| Screw Diameter |

φ50 mm |

φ60 mm |

φ70 mm |

φ80 mm |

φ90 mm |

| Screw L/D Ratio |

25:1 |

26:1 |

26:1 |

26:1 |

26:1 |

| Extrusion Amount |

70 kg/hr |

110 kg/hr |

160 kg/hr |

220 kg/hr |

300 kg/hr |

| Outlet Wire |

φ0.75-4 mm |

φ0.8-8 mm |

φ1.5-12 mm |

φ2-18 mm |

φ6-50 mm |

| Main Motor |

11 KW |

18.5 KW |

37 KW |

55 KW |

75 KW |

| Cooling Device |

U type |

U type |

U type |

U type |

U type |

| Storage Rack |

Horizontal |

Horizontal |

Horizontal |

Horizontal |

Horizontal |

| Traction Power |

4 KW |

4 KW |

4 KW |

5.5 KW |

11 KW |

| Production Speed |

500 m/min (Max.) |

450 m/min (Max.) |

400 m/min (Max.) |

350 m/min (Max.) |

300 m/min (Max.) |

| Take-up Spool |

φ400-630 mm |

φ400-630 mm |

φ500-630 mm |

φ800-1000 mm |

φ1000-1250 mm |

| Coiling Method |

Automatic |

Automatic |

Automatic |

Automatic |

Automatic |

NH-BV Fire-resistant Wire Extrusion Line Application

The NH-BV fire-resistant wire extrusion line is a complete set of equipment designed for manufacturing fire-resistant polyvinyl chloride insulated wires that comply with the GB/T 19216 standard. By adding special fire-resistant materials (such as mica tape) to the insulation layer, the wires can maintain a smooth circuit for 90 minutes in flames above 750 ℃.