Model 50-90Screw Diameter φ50-90 mmL/D Ratio 26:1Extrusion Output 70-300 kg/hrMain Motor 11-75 KWOutlet Diameter 0.75-50 mmSpeed 300-500 m/minApplication BV, BVR, ZR-BV, RV, etc. wire

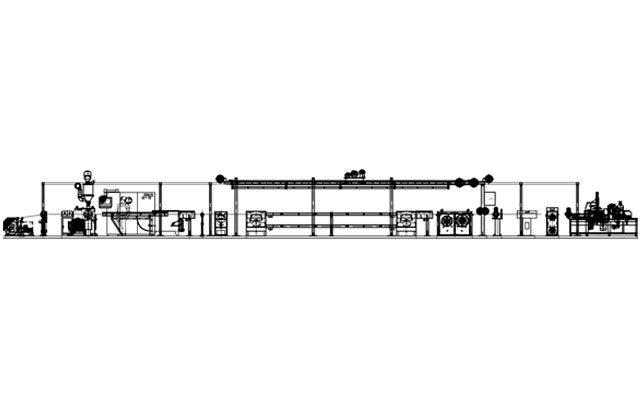

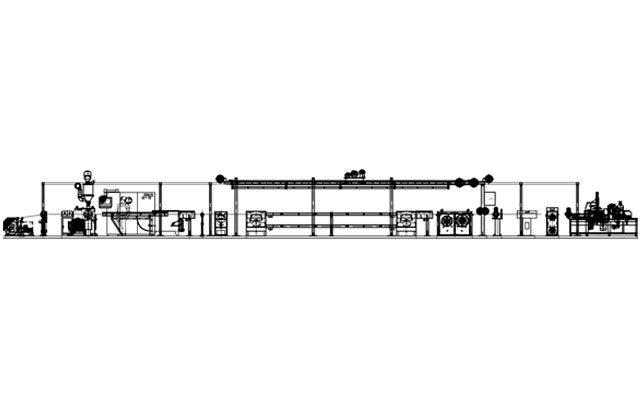

ZR-BV Flame-retardant Wire Extrusion Line

ZR-BV wire is a flame-retardant polyvinyl chloride insulated wire. The main characteristic of this type of wire is its flame retardant properties, which can delay the spread of flames to a certain extent. It is usually used for electrical wiring inside buildings and is more suitable for occasions that require flame retardant requirements. The conductor material of ZR-BV wire is generally copper, and the insulation layer is made of polyvinyl chloride, which has good insulation performance and durability.

The ZR-BV flame-retardant wire extrusion line is a specialized system for manufacturing flame-retardant PVC-insulated building wires (ZR-BV type) compliant with GB/T 19666 (China) and IEC 60332 (international) standards. It integrates flame-retardant additive dosing and high-precision extrusion for enhanced fire safety.

Composition of Production Line

The ZR-BV flame-retardant wire extrusion line mainly includes the following core equipment:

Pay off Stand: Release copper/aluminum conductors to maintain stable tension.

Preheating Unit: Heat the conductor to improve insulation adhesion.

Extruder: Melt PVC/XLPE and evenly coat the conductor.

Cooling Tank: Segmented cooling and shaping insulation layer.

Haul off: Control the speed of the production line.

Take-up Reel: Automatic winding of finished wires.

Testing Equipment: Spark tester, laser diameter measuring system, etc.

Process Flow

Pay-off → Preheating → Extrusion coating → Cooling and shaping → Spark detection → Printing → Take-up.

ZR-BV Flame-retardant Wire Extrusion Line Datasheet

| Model |

50 |

60 |

70 |

80 |

90 |

| Pay-off Type |

Active or passive |

Active or passive |

Active or passive |

Active or passive |

Active or passive |

| Screw Diameter |

φ50 mm |

φ60 mm |

φ70 mm |

φ80 mm |

φ90 mm |

| Screw L/D Ratio |

25:1 |

26:1 |

26:1 |

26:1 |

26:1 |

| Extrusion Amount |

70 kg/hr |

110 kg/hr |

160 kg/hr |

220 kg/hr |

300 kg/hr |

| Outlet Wire |

φ0.75-4 mm |

φ0.8-8 mm |

φ1.5-12 mm |

φ2-18 mm |

φ6-50 mm |

| Main Motor |

11 KW |

18.5 KW |

37 KW |

55 KW |

75 KW |

| Cooling Device |

U type |

U type |

U type |

U type |

U type |

| Storage Rack |

Horizontal |

Horizontal |

Horizontal |

Horizontal |

Horizontal |

| Traction Power |

4 KW |

4 KW |

4 KW |

5.5 KW |

11 KW |

| Production Speed |

500 m/min (Max.) |

450 m/min (Max.) |

400 m/min (Max.) |

350 m/min (Max.) |

300 m/min (Max.) |

| Take-up Spool |

φ400-630 mm |

φ400-630 mm |

φ500-630 mm |

φ800-1000 mm |

φ1000-1250 mm |

| Coiling Method |

Automatic |

Automatic |

Automatic |

Automatic |

Automatic |

ZR-BV Flame-retardant Wire Extrusion Line Application

The ZR-BV flame-retardant wire extrusion line is a specialized system for manufacturing flame-retardant PVC-insulated building wires (ZR-BV type) compliant with GB/T 19666 (China) and IEC 60332 (international) standards. It integrates flame-retardant additive dosing and high-precision extrusion for enhanced fire safety.