Model ML/MS SeriesNo. of Wires 1Inlet Wire Diameter 2.5-3.5 mmOutlet Wire Diameter 0.4-2.8 mmLine Speed (Max.) 720-1800 m/minNo. of Dies (Max.) 9-17Motor Power 30-110 KWTake-up Power 7.5-30 KWConductor Type Copper, aluminum, and related alloys wires.Drive System Frequency converter

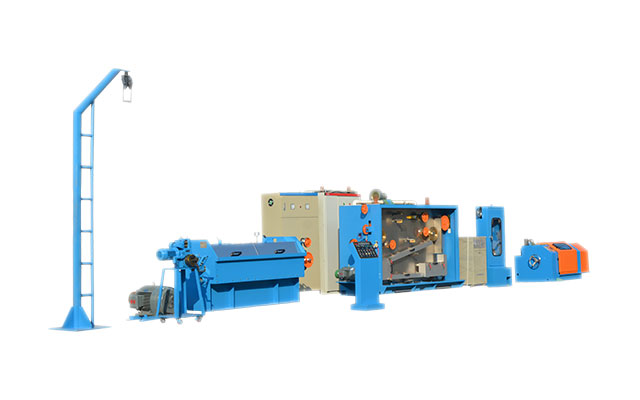

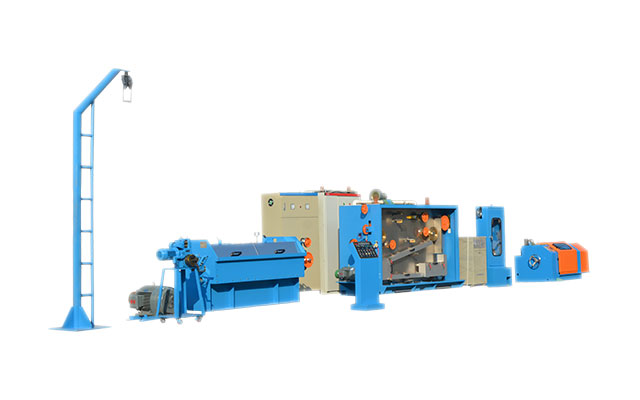

Medium Aluminum Wire Drawing Machine

The medium diameter aluminum wire drawing machine is a specialized equipment used to process larger diameter aluminum rods (usually 9.5 mm or 12 mm) into medium diameter (usually 2.8 mm to 0.4 mm) aluminum wires through multiple passes of stretching. It is widely used in fields such as wire and cable, power transmission, and electrical materials.

Major Component

Pay-off DeviceSupports over end or elevated wire laying to ensure continuous feeding;

Stretching host: integrates multiple molds and gear transmission systems to complete step-by-step stretching;

Lubrication and Cooling SystemFully immersed or spray lubrication to reduce friction and temperature rise;

Tension Control DevicePneumatic swing arm or PID control to maintain constant tension;

Take-up DeviceShaftless/shaft type cable take-up machine, supporting large capacity winding.

Medium Aluminum Wire Drawing Machine Datasheet

| Item/Model |

ML Series |

MS Series |

| No. of Wires |

1 |

1/2 |

| Inlet Wire Dia. |

3.0-3.5 mm |

2.5-3.5 mm |

| Outlet Wire Dia. |

0.5-2.8 mm |

0.4-2.0 mm |

| Line Speed (Max.) |

720-1200 m/min |

1800 m/min |

| No. of Dies (Max.) |

9-17 |

17 |

| Drawing Wheel |

φ250-280 mm |

/ |

| Fixed Speed Wheel |

/ |

/ |

| Main Motor |

30-45 KW |

55-110 KW |

| Take-up Motor |

7.5-15 KW |

15-30 KW |

| Annealing Motor |

5.5-11 kW |

9-24 KW |

| Control Mode |

Double frequency converter |

/ |

| Traverse Method |

Gear motor |

Gear motor |

| Lubrication |

Total immersion / Spray type |

/ |

| Brake |

Pneumatic brake |

Pneumatic brake |

| Take-up Spool |

φ630 mm |

φ630 mm |

Medium Aluminum Wire Drawing Machine Application

The medium diameter aluminum wire drawing machine has the characteristics of high efficiency, stability, and energy saving. This equipment is widely used in various industries such as wire and cable, power transmission, and electrical materials. Specifically, as follows:

Power Transmission and Cable ManufacturingOverhead conductors (such as steel cored aluminum stranded wire ACSR, aluminum alloy stranded wire AAAC);

Aluminum wire has the characteristics of lightweight, high conductivity, and corrosion resistance, and is suitable for high-voltage transmission lines.

The aluminum wire produced by the wire drawing machine is twisted to form a high-strength, large-span overhead cable.

Power Cable ConductorAluminum core conductors used for manufacturing low and medium voltage power cables, such as VV, YJV and other types of cables.

Medium diameter aluminum wire can be used as the conductive core of cables, wrapped in insulation layer, and used in urban power grids, industrial electricity and other scenarios.

Electrical Materials and Electromagnetic WiresTransformer Winding Wire

After drawing, aluminum wire can be used as winding material for dry-type transformers and oil immersed transformers.

Compared to copper wire, aluminum wire has a lower cost and is suitable for large capacity transformers.

Enamel Eire (electromagnetic wire)

After further thinning, annealing, and painting, medium diameter aluminum wire is made into enameled aluminum wire, which is used for electromagnetic components such as motors, generators, and inductors.

Communication and Fiber Optic Composite CableFiber Optic Composite Overhead Ground Wire (OPGW)

Aluminum wire serves as the outer armor material, protecting the internal optical fibers while also providing conductivity and mechanical support.

Communication Cable Shielding Layer

After weaving or wrapping aluminum wire, it can be used as a shielding layer for communication cables (such as CAT5, CAT6) to improve anti-interference ability.

Industrial and Special PurposeAluminum Wire for Welding

Aluminum welding wire used for MIG welding (Metal Inert Gas Welding) requires processes such as wire drawing and annealing.

Automotive Wiring Harness

The trend of lightweighting in new energy vehicles is driving the application of aluminum wire in automotive wiring harnesses, replacing some copper wires.

Metal Woven Mesh

Aluminum wire can be used to manufacture industrial materials such as shielding nets and protective nets.