Model FS22No. of Wires 1Inlet Wire Diameter 0.8-1.2 mmOutlet Wire Diameter 0.1-0.32 mmLine Speed (Max.) 1500 m/minNo. of Dies (Max.) 22Motor Power 18.5 kWTake-up Power 3.7 KWConductor Type Brass wireDrive System Frequency converter

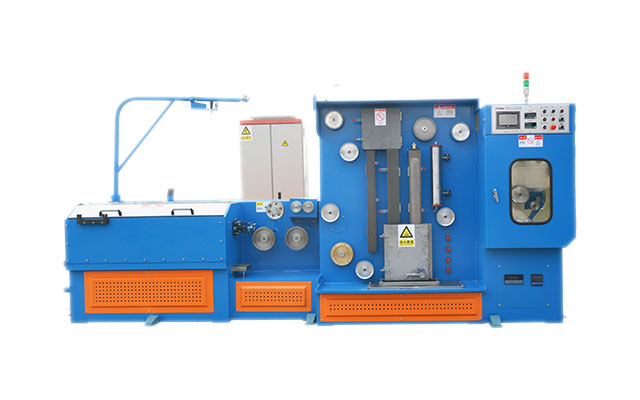

FS22 Fine Brass Wire Drawing Machine Line with Continuous Annealing

FS22 fine brass wire drawing machine line with continuous annealing is a key equipment specifically designed to process medium brass wire with a diameter of 0.8 mm to 1.2 mm into fine brass wire with a diameter of 0.1 mm to 0.32 mm through multiple passes of stretching.

Main Structure

Pay-off system: Active/passive pay-off, equipped with tension control.

Wire drawing host: Mold box, wire drawing wheel (tower wheel or inline type), lubrication and cooling system.

Annealing device: Eliminates work hardening and improves wire flexibility.

Take-up system: I-shaped wheel or double disc winding, precise wire arrangement ensures neat winding.

Control system: PLC+human-machine interface (HMI), realizing the adjustment of parameters such as speed, tension, temperature, etc.

FS22 Fine Brass Wire Drawing Machine Line with Continuous Annealing Datasheet

| Item/Model |

FS22 |

| No. of Wires |

1 |

| Inlet Wire Dia. |

0.8-1.2 mm |

| Outlet Wire Dia. |

0.1-0.32 mm |

| Line Speed (Max.) |

1500 m/min |

| No. of Dies (Max.) |

22 |

| Slip Ratio of M/C |

/ |

| Slip Ratio of Fixed Speed Wheel |

/ |

| Main Motor |

18.5 kW |

| Take-up Motor |

3.7 KW |

| Annealing Motor |

12 KVA |

| Annealing Method |

DC four-section annealing |

| Traverse Method |

/ |

| Brake |

Pneumatic brake |

| Take-up Spool |

φ250 mm |

FS22 Fine Brass Wire Drawing Machine Line with Continuous Annealing Application

FS22 fine brass wire drawing machine line with continuous annealing plays an irreplaceable role in modern industry. Its main application areas and technical characteristics are as follows:

Manufacturing of Electronic ComponentsMicro connectors: used for precision connectors such as Type-C interfaces for mobile phones/computers, SIM card slots, semiconductor leads, bonding wires for chip packaging, relay contacts, and key conductive components for electromagnetic relays.

Precision Instrument FieldMedical equipment: orthodontic archwire, endoscope guide wire.

Optical instruments: barrel focusing thread, precision gear shaft, special surface coating treatment.

High End Consumer GoodsJewelry craftsmanship: 18K gold alloy jewelry skeleton, precision woven jewelry thread, surface polishing requires mirror effect.

Instrument manufacturing: piano stringer components, brass instrument pistons.

Industrial Special ApplicationsMicro spring: a buffer component for electronic devices.

3D printing materials: substrates for sintering metal powders.