Model 50-90Screw Diameter φ50-90 mmL/D Ratio 26:1Extrusion Output 70-300 kg/hrMain Motor 11-75 KWOutlet Diameter 0.75-50 mmSpeed 300-500 m/minApplication BV, BVR, BVN, RV, etc. insulated wire

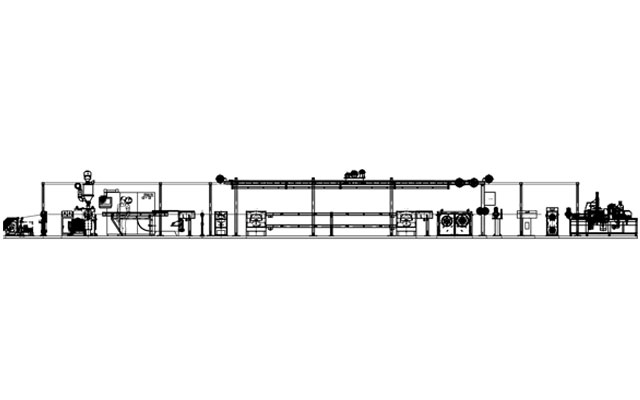

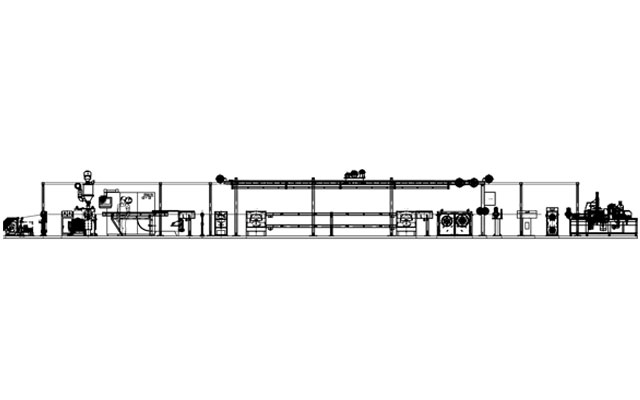

BV Wire Extrusion Line

BV wire, also known as plastic copper wire, is a copper core PVC insulated distribution wire. B represents the category of electrical wiring, and V represents insulation made of polyvinyl chloride. It is suitable for cables and wires used in power plants, daily electrical appliances, instruments, and telecommunications equipment with AC voltage of 450/750V and below.

The BV wire extrusion line is a complete set of equipment specifically used for producing BV type copper core polyvinyl chloride insulated wires. Through extrusion technology, PVC insulation material is uniformly coated on the surface of copper conductors to manufacture building wires that comply with the national standard.

Composition of Production Line

The BV wire extrusion line mainly includes the following core equipment:

Pay off Stand: Release copper/aluminum conductors to maintain stable tension.

Preheating Unit: Heat the conductor to improve insulation adhesion.

Extruder: Melt PVC/XLPE and evenly coat the conductor.

Cooling Tank: Segmented cooling and shaping insulation layer.

Haul off: Control the speed of the production line.

Take-up Reel: Automatic winding of finished wires.

Testing Equipment: Spark tester, laser diameter measuring system, etc.

Process Flow

Pay-off → Preheating → Extrusion coating → Cooling and shaping → Spark detection → Printing → Take-up.

BV Wire Extrusion Line Datasheet

| Model |

50 |

60 |

70 |

80 |

90 |

| Pay-off Type |

Active or passive |

Active or passive |

Active or passive |

Active or passive |

Active or passive |

| Screw Diameter |

φ50 mm |

φ60 mm |

φ70 mm |

φ80 mm |

φ90 mm |

| Screw L/D Ratio |

25:1 |

26:1 |

26:1 |

26:1 |

26:1 |

| Extrusion Amount |

70 kg/hr |

110 kg/hr |

160 kg/hr |

220 kg/hr |

300 kg/hr |

| Outlet Wire |

φ0.75-4 mm |

φ0.8-8 mm |

φ1.5-12 mm |

φ2-18 mm |

φ6-50 mm |

| Main Motor |

11 KW |

18.5 KW |

37 KW |

55 KW |

75 KW |

| Cooling Device |

U type |

U type |

U type |

U type |

U type |

| Storage Rack |

Horizontal |

Horizontal |

Horizontal |

Horizontal |

Horizontal |

| Traction Power |

4 KW |

4 KW |

4 KW |

5.5 KW |

11 KW |

| Production Speed |

500 m/min (Max.) |

450 m/min (Max.) |

400 m/min (Max.) |

350 m/min (Max.) |

300 m/min (Max.) |

| Take-up Spool |

φ400-630 mm |

φ400-630 mm |

φ500-630 mm |

φ800-1000 mm |

φ1000-1250 mm |

| Coiling Method |

Automatic |

Automatic |

Automatic |

Automatic |

Automatic |

BV Wire Extrusion Line Application

The BV wire extrusion line is a complete set of equipment specifically used for producing BV type copper core polyvinyl chloride insulated wires. Through extrusion technology, PVC insulation material is uniformly coated on the surface of copper conductors to manufacture building wires that comply with the national standard.